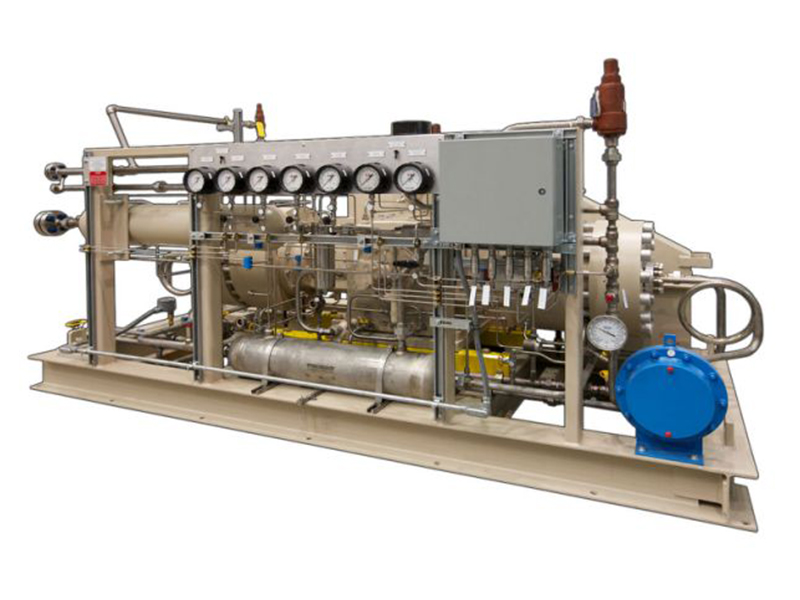

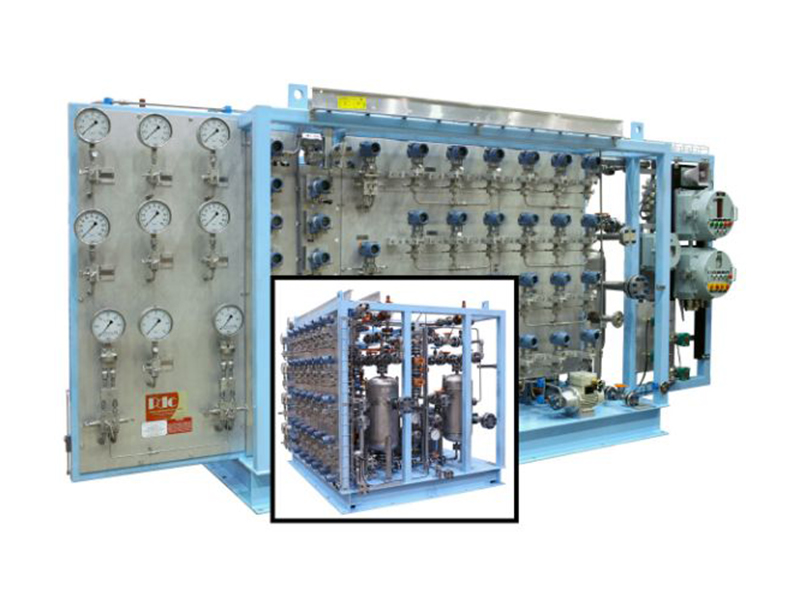

PDC diaphragm compressor

Classification:

Key words:

Product Details

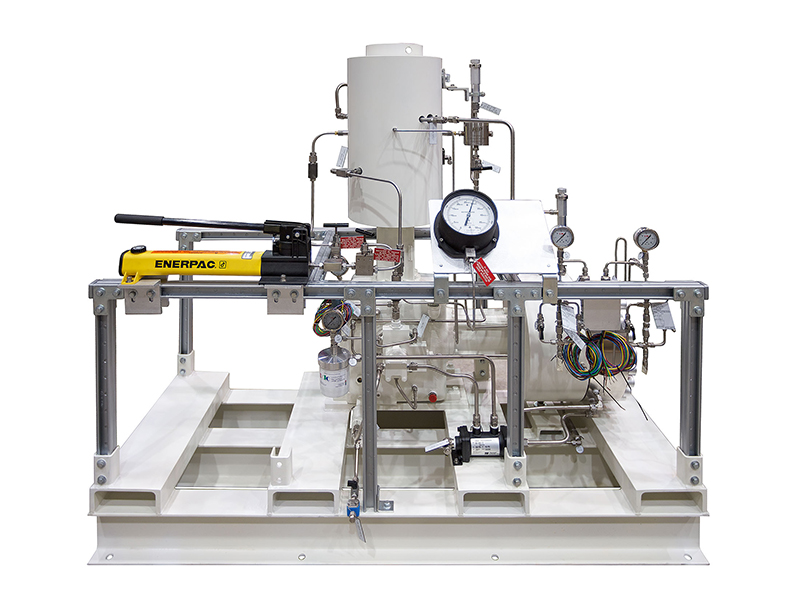

Working principle of three-layer metal diaphragm compressor

A diaphragm compressor is a positive displacement compressor consisting of a hydraulic system and a gas compression system.

The hydraulic system uses a linear reciprocating piston driven by a motor to compress the crankshaft of the compressor body, thereby driving the reciprocating motion of the piston stroke.

The hydraulic piston moves in the cylinder to push the hydraulic oil. Hydraulic oil is also used as lubricating oil, on the one hand, to lubricate the moving parts of the compressor unit, and on the other hand, hydraulic oil is used to pressurize the process gas side with a metal diaphragm.

The gas compression system consists of a gas-side head assembly, a three-layer metal diaphragm group, and compressor suction and exhaust valves.

After the hydraulic oil is pumped to the oil side of the diaphragm group, the reciprocating movement of the piston causes the hydraulic oil entering the oil side of the head to push the diaphragm group towards the gas side of the head, thus changing the volume of the compression chamber on the gas side of the head, and realizing the inflow and outflow of process gas into and out of the compressor through the compressor suction and exhaust valves.

Diaphragm compressor characteristics

- Diaphragm compressors do not require piston rings. There are no particles generated by piston ring wear; there is no risk of particles entering the vehicle's hydrogen supply system through downstream filters, blocking pipes and valves, and causing dust explosions.

- The completely sealed compression chamber prevents hydrogen leakage and eliminates hydrogen loss. For routine overhaul and maintenance, experienced maintenance personnel can complete the work within 2-4 hours.

- Simple system structure. High compression ratio, low energy consumption, high efficiency.

- Under normal use, the gas valve has a service life of 8000-10000 hours without failure.

- Using non-flammable hydraulic oil and corrosion-resistant components, it can be used to handle corrosive or oxidizing gases, ensuring operational safety and extending the service life of operating components.

- The leak detection system and safety interlock device will alarm and/or shut down the compressor when an abnormality is detected. The automatic unloading system achieves maximum efficiency without the need for the operator to start/restart the compressor.

- The three-stage diaphragm group ensures that the process gas is completely isolated from the hydraulic oil. No dynamic seals are used, eliminating the possibility of carrying sealing particles into the airflow. No filters and oil removal systems are required, and hydraulic oil will not escape into the process gas, ensuring pollution-free gas compression.

- The diaphragm cavity profile is carefully designed to control the stress in the diaphragm to achieve a uniform stress distribution. The diaphragm surface uses a special manufacturing process to improve fatigue resistance and extend the life of the metal diaphragm.

- Static sealing ensures that no process gas escapes into the crankcase, eliminating the need for crankcase purging or exhaust. Detecting the integrity of the process gas system prevents process gas leakage into the atmosphere, ensuring a friendly working environment and protecting the atmosphere.

- Unique oil distribution technology is used in the hydraulic system to eliminate pressure difference and gradient, and an automatic oil injection pump, a positive displacement high-pressure injection pump, and a bypass relief valve are used to achieve simple and easy start-up operation.

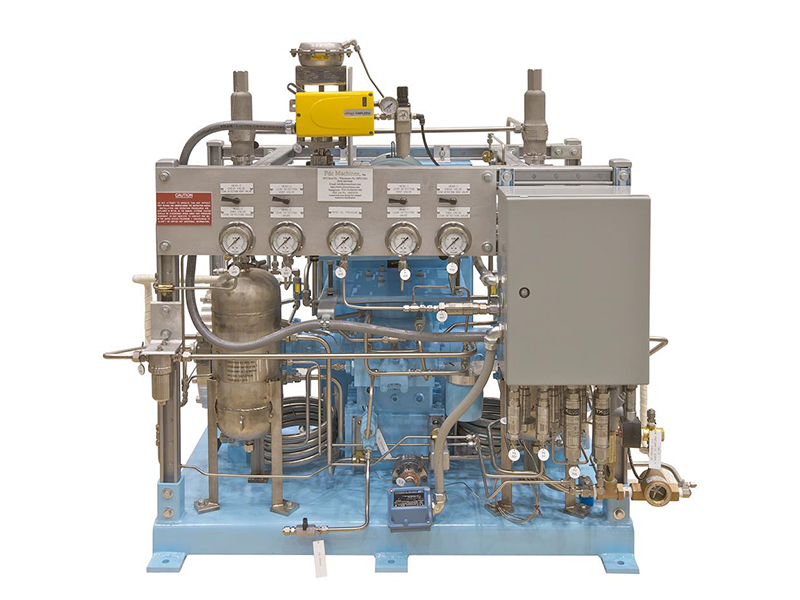

PDC hydrogen diaphragm compressor

- Pollution-free

- Leak-free

- Low vibration

- Low noise

- High efficiency

- Low energy consumption

Simple and quick product after-sales maintenance

All our wearing parts are in stock. The delivery time is usually 24-48 hours, ensuring that users can get quick response support and don't have to worry about unexpected downtime.

Long trouble-free operation cycle, strong adaptability to harsh conditions

Whether it is diaphragms, O-rings, process check valves and fittings, or even complete crankcases, crankcase components, and process heads, which are non-wearing parts, we also have stock available for quick shipment.

Our spare parts are clearly marked for easy identification. 100% inspected and the quality is fully guaranteed.

PDC hydrogen diaphragm compressor specifications (for hydrogen refueling stations)

|

Model |

Maximum inlet temperature (°C) |

Maximum inlet pressure MPa(G) |

Minimum inlet pressure MPa(G) |

Maximum exhaust temperature (°C) |

Exhaust pressure MPa(G) |

Flow rate/day (KG, calculated for 12 hours) |

|

PDC-13-1000(100)/3500(100) |

30 |

1.5 |

-- |

197 |

22 |

550 |

|

PDC-13-7500(100) |

30 |

20 |

20 |

194 |

45 |

500 |

|

PDC-13-7500(100)/7500(100) |

30 |

20 |

5 |

194 |

45 |

1000 |

|

PDC-13-3500(80)/7500(100) |

10 |

20 |

5 |

194 |

45 |

750 |

|

PDC-13-3500(100)/7500(100) |

10 |

10.3 |

5 |

194 |

45 |

1000 |

|

PDC-13-15000(75) |

30 |

45 |

30 |

173 |

87.5 |

500 |

|

PDC-13-7500(100)/15000(75) |

30 |

20 |

20 |

197 |

87.5 |

500 |

|

|

|

|

|

| Hydrogen H2 | Silane Silane | Carbon monoxide CO | Helium He | Hydrogen H2 |

| Location: Global Process gas: Hydrogen Compressor Specification: PDC4-2500-15000(150) 2-stage Flow rate: 100KG/day, Outlet pressure: 100MPa(G) Power: 30kW |

Location: USA Process gas: Silane Compressor Specification: PDC3-550-550(50) Flow rate: 5 Nm3/hour, Outlet pressure: 0.9 MPa(G) Power: 4 kW |

Location: USA Process gas: Carbon monoxide Compressor Specification: PDC13-1000-2500(50) 2-stage Flow rate: 245 Nm3/hour, Outlet pressure: 16.5 MPa(G) Power: 55 kW |

Location: Global Process gas: Helium Compressor Specification: PDC3-3000-7500 2-stage Flow rate: 20 Nm3/hour, Outlet pressure: 51.7 MPa(G) Power: 7.5 kW |

Location: India Process gas: Hydrogen Compressor Specification: PDC4-600-600(130) Flow rate: 350 Nm3/hour, Outlet pressure: 4 MPa(G) Power: 22 kW |

Related Products

Water electrolysis hydrogen production

Water electrolysis hydrogen production

Water electrolysis hydrogen production